What Makes High Temperature HEPA Filters Different from Standard HEPA Filters?

HEPA filters are essential components in environments where clean air is critical, such as laboratories, pharmaceutical production lines, and cleanrooms. However, not all HEPA filters are designed the same. The main difference between a standard HEPA filter and a High Temperature HEPA Filter lies in their ability to perform under different thermal conditions. Here’s a breakdown of what makes high temperature HEPA filters different—and necessary—in certain applications.

1. Heat Resistance

The primary distinction is temperature tolerance. Standard HEPA filters are generally designed for use in environments with ambient temperatures, typically up to 80°C. In contrast, high temperature HEPA filters are engineered to withstand temperatures as high as 250°C or more. This makes them suitable for sterilization tunnels, drying ovens, and other high-heat industrial processes.

2. Filter Media Material

Standard HEPA filters usually use synthetic fibers or treated paper as their filtration media. These materials perform well under normal conditions but cannot maintain structure or efficiency when exposed to high heat. High temperature HEPA filters use heat-resistant glass microfiber media, which maintains its integrity and filtration performance even in extreme temperatures.

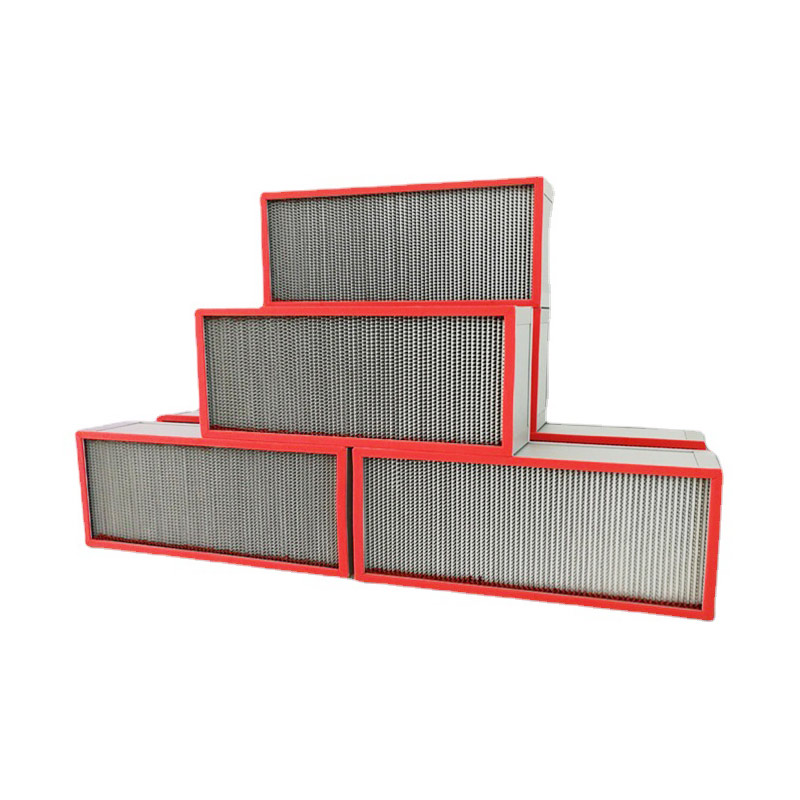

3. Frame Construction

The frame material also varies significantly. Standard filters may use plastic, aluminum, or wood frames, which are not suited for high temperatures. High Temperature Filters are typically built with stainless steel or galvanized steel frames. These materials resist thermal deformation and ensure that the filter maintains a reliable seal within the housing.

4. Sealants and Adhesives

Sealants used in standard HEPA filters are often polyurethane-based, which can degrade or off-gas at high temperatures. High temperature HEPA filters use specialized silicone or ceramic sealants that can withstand prolonged exposure to heat without compromising performance or safety.

5. Applications

Due to their unique construction, high temperature HEPA filters are used in specialized environments where elevated temperatures are part of the operation. Common applications include pharmaceutical sterilization lines, cleanroom ovens, food and beverage processing equipment, and laboratories requiring sterile, high-temperature airflow. Standard HEPA filters are more common in HVAC systems, office cleanrooms, and general air purification equipment where extreme heat is not a factor.

6. Regulatory Requirements

High temperature HEPA filters are often subject to stricter certification standards. These include compliance with EN 1822, ISO 29463, and industry-specific requirements such as GMP or FDA guidelines for clean manufacturing environments. While standard HEPA filters also meet filtration efficiency standards, they are not always tested for thermal resistance or fire safety unless explicitly required.

7. Maintenance and Durability

Because they are built with high-performance materials, high temperature HEPA filters often last longer in harsh environments. However, they also require careful installation and handling due to the fragile nature of the media and seals. Regular integrity testing is recommended to ensure ongoing compliance and efficiency.

Conclusion

While both types of HEPA filters are designed to remove harmful airborne particles, high temperature HEPA filters are specialized for extreme environments where standard filters would fail. Their ability to maintain high filtration efficiency under continuous heat makes them essential for certain industries. When selecting a HEPA filter, it's critical to understand the temperature conditions of your application and choose the filter that ensures both safety and performance.